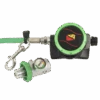

CRESSI Mc9 Sc + Compact Pro Regulator

$369.00 Original price was: $369.00.$99.99Current price is: $99.99.

- Fast and Secure Payments

- Shop with confidence, enjoy free returns.

- We take quality seriously.

- Fast reliable delivery options

In order to achieve extremely high performance in low temperature environments, the second stage in particular was designed with the special thermoconductive thermoplastic neopolymer that has the capacity to transfer heat like a metal while preserving the design flexibility, chemical resistance, and physical and mechanical properties of a conventional thermoplastic. That is, it makes it possible to drastically reduce the weight while delivering heat conductivity on a par with metal cases. Thanks to this material and a specially conceived purge valve, it passes en 250 cold water tests.

TECHNICAL FEATURES

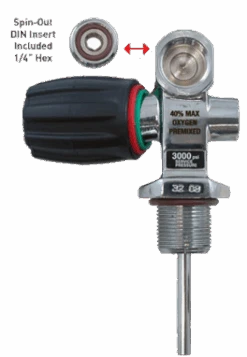

• Technical features 1st stage

• Balanced diaphragm (seal chamber for mc9sc)

• 2 outlets hp 7/16 unf

• 4 outlets mp 3/8 unf

• Service pressure: 300 bar (4350 psi) din version,232 bar (3365 psi) yoke version

• Calibration pressure: 10 bar

• Brass body electroless nickel plated

• High capacity conical fi lter electroless nickel plated

• Aisi 316 removable nozzle

• Hyper-balancing

• Anti-pressure drop pneumatic spring

• Setting spring: stainless steel with micropeening treatment

• Replaceable cylinder with anti-friction and anti-corrosion properties

• Elastomer protector

• Flow rate: 4500 l/min

• Yoke version weight: 650 gr

• Din version weight: 510 gr

• Technical features 2nd stage

• Improved reliability front cover (more impact resistant)

• Downstream system

• Adjustable venturi effect

• Patented antifriction lever

• Thermoconductive technopolymer body

• Big purge button

• Anti-scratch surface

• Bayonet-type cap holder with security lock

• Removable exhaust tee

• Weight without hose: 140 gr

• Combination performance

• Average cracking effort 7.5 mbar

• Average breathing effort 1 j/l

• Jacketed hose extremely light and flexible weight: 153 gr

• Certification en250/2014 for cold water

| Stage Style | Yoke, DIN |

|---|

Reviews

There are no reviews yet.